Overview

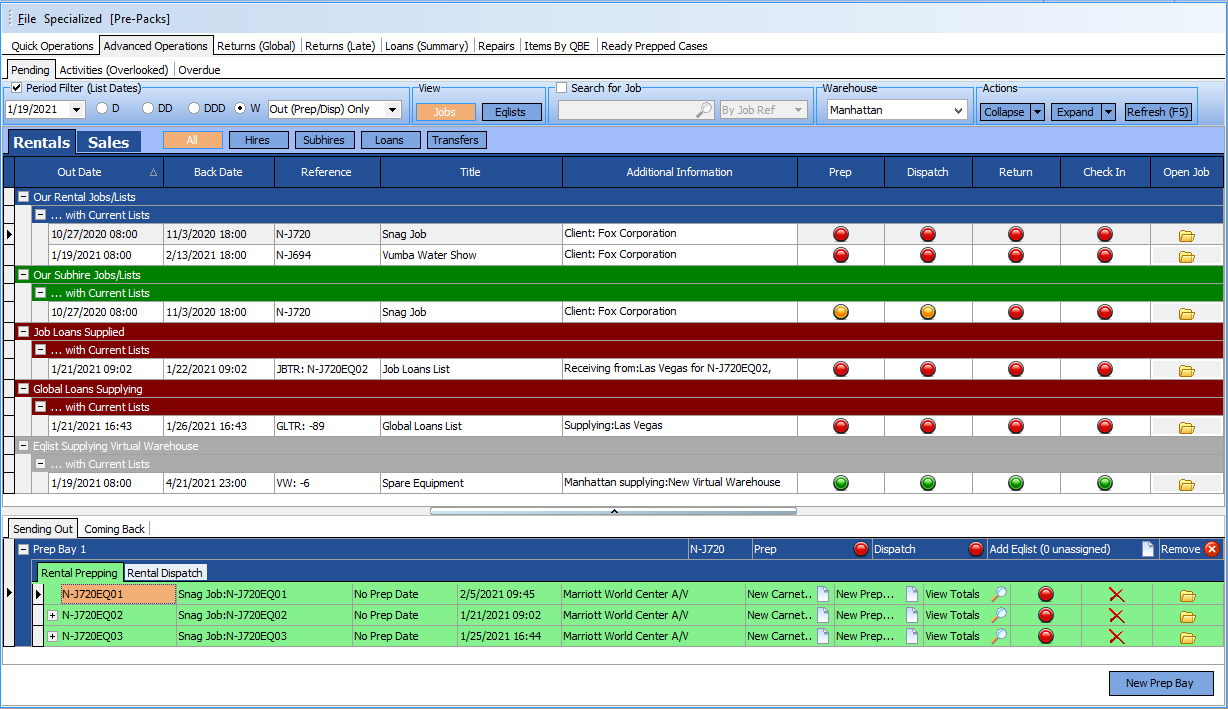

The Warehouse Book is where scheduled hires, subhires, sales, sales orders and inter-warehouse loans are processed. So hires need to be prepped and dispatched, subhires received in and made available for hire, etc.

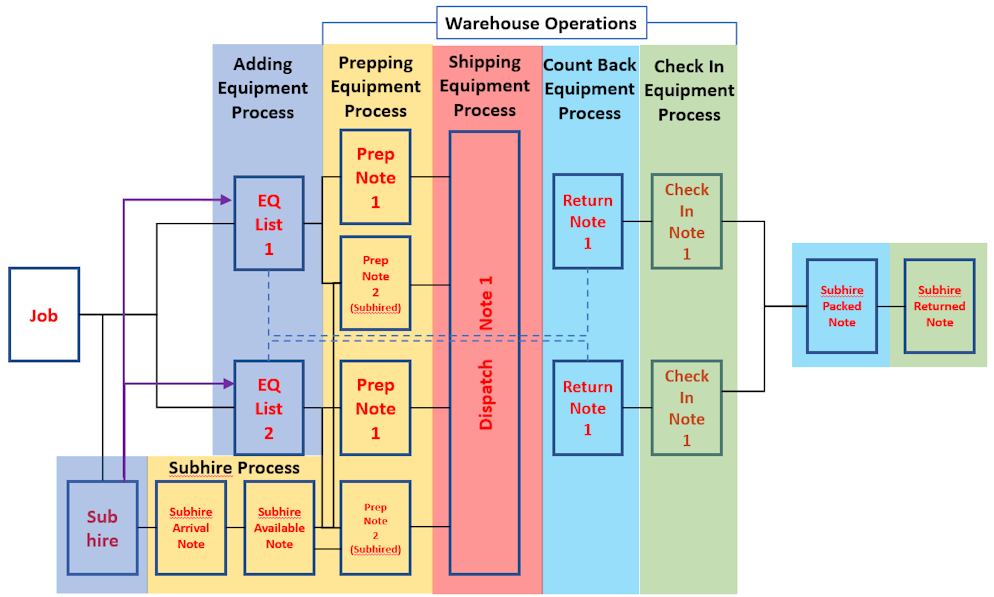

The flow of the typical work process is shown here:

The process splits into two core areas, mapping to the Rental and Sales pages in the Job Book, with several types of equipment movement for each area:

RENTAL

Equipment Lists - For sending equipment to clients

| 1. | You allocate the lists to a Prep Bay. You can have one Prep Bay per list or multiple lists can be placed into one Prep Bay. Typically, a job will have only 1 Prep Bay. |

| 2. | You then Prep the equipment via Prep Notes which document what has been prepped in the Prep bay and what still needs to be prepped to meet the requirements of the lists. |

| 3. | Once the equipment has been Prepped it can be Dispatched on one or more Dispatch Notes according to whether it went out in one batch or many batches. |

| 4. | On Return you receive the equipment back from clients and in create one or more Returns Notes. |

| 5. | The equipment now needs to be Checked In (inspection and returning to shelf). |

Job Subhires - For renting in equipment for a specific job

| 1. | Select the Subhire(s) you wish to process by allocating them to a Prep Bay. |

| 2. | You receive in the equipment from a Subhire and create a Subhires Arrived Note. |

| 3. | Having checked the equipment you raise a Subhires Available Note. |

| 4. | Subhires are then processed on an Equipment List's Prep Note (Subhire) separately from warehouse equipment. |

| 5. | The equipment is then Dispatched, Returned, and Checked In along with your owned equipment. |

| 6. | Once the equipment is returned and checked in, you then create a Subhire Packed Note |

| 7. | Finally the Subhire need to go back to it's supplier so you create a Subhires Returned Note. |

Global Subhires. - Rather than equipment being allocated to a specific job, the equipment is added to general stock for the sub hire period and is treated as local Warehouse stock during the period.

Job Transfers. - This is where equipment is booked for in specific equipment list from one Warehouse and is using equipment supplied from another Warehouse

| 1. | The sending Warehouse first allocates the equipment transfer request to a Prep Bay. |

| 2. | The sending Warehouse then dispatches the equipment to the receiving Warehouse on a Loans Dispatch Note |

| 3. | The receiving Warehouse creates a Prep bay to receive the goods into the Warehouse. |

| 4. | The receiving Warehouse then creates a Loan Received Note. |

| 5. | The Loaned Equipment is then processed on an Equipment List's Prep Note (Loans) separately from the receiving warehouse equipment. |

| 6. | The equipment is then Dispatched, Returned, and Checked In along with your owned equipment. |

| 7. | After the job is finished the receiving Warehouse creates a Loan Returns Note and ships the equipment back |

| 8. | The original (sending) Warehouse creates a Loans Back Note to say they have received their equipment back. |

Global Transfers - Where equipment is loaned for a period of time from one Warehouse to another and then is treated as local stock for the receiving Warehouse during the period of the loan.

SALES

Sales Lists - For supplying equipment to clients

| 1. | You allocate the lists to a Sales Bay. You can have one Sales Bay per list or multiple lists can be placed into one Sales Bay. Typically, a job will have only 1 Prep Bay. |

| 2. | You then Pull the equipment via Pull Notes which document what has been pulled in the Prep bay and what still needs to be pulled to meet the requirements of the lists. |

| 3. | Once the equipment has been pulled it can be Dispatched on one or more Dispatch Notes according to whether it went out in one batch or many batches. Dispatching depletes stocklevels with new stock OUT entries in the Audit Trail. |

| 4. | Normally this would be the end of the process, but should your customer send sales items back, they can be Returned and put back into stock with the creation of Return Notes and Sales On Shelf Notes. This will increase stocklevels with new stock IN entries in the Audit Trail. |

Sales Order Lists - For purchasing equipment.

| 1. | You allocate the lists to a Sales Bay. You can have one Sales Bay per list or multiple lists can be placed into one Sales Bay. |

| 2. | You then receive the stock in via Good In Notes which document what has been pulled in the Sales Bay and what still needs to be pulled to meet the requirements of the lists. |

| 3. | Once the equipment has been received in you can now Stock In on one or more Stock In Notes according to whether it came in via one batch or many batches. A Stock In increases stocklevels with new stock In entries in the Audit Trail. Once stocked in you have the opportunity to allocate barcodes in the Stock In Notes. |

| 4. | Normally this would be the end of the process, but should you need to send sales items back the supplier, they can be Returned and put back into stock with the creation of Sales Order Rejection Notes and Returns Notes. This will decrease stocklevels with new stock OUT entries in the Audit Trail. |

It will be noted that in all the above processes, there are two pairs of actions: Prep & Dispatch, Return & Check In, Subhires Arrived & Subhires Available, etc. This allows for very accurate processing, should this be desired; however, each note, when completed has a "macro" action available that allows the next stage (e.g. Dispatch) to be completed with the single click on a button.